Spotlight! Autonomous Layout

Simplicity. Accuracy. Transparency across projects. Less joint pressure. These are some obvious benefits of autonomous layout. Here is some information on how autonomous indoor and outdoor layout is coming into the construction industry.

Visible conflict depiction on site, clean floors needed to print leading to decreased tripping hazards, avoided rework, promoted collaboration with models and on site, and, of course, fast and accurate layout. With the capability of laying out multiple trades at once and printing text, collaboration and compressed schedules are potential benefits as well.

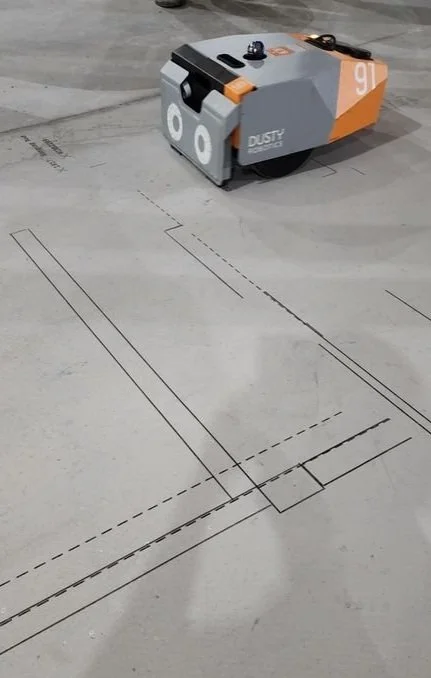

Dusty Robotics, a trail blazer in the space, provides fast and accurate autonomous layout with FieldPrint. Compatible with both lasers (included with the hardware) or total stations, the Dusty Robot has flexibility when it comes to execution. The lasers have higher accuracy, with 1/16” while the total station has an accuracy of ⅛”. FieldPrint works off of an uploaded control point file.In a case study by Turner, Dusty's FieldPrinter empowered the completion of 42,000 sqft of interior layout in 5 days with one person. Available in the US today, FiledPrint is priced by amount printed.

HP SitePrint is making their way into the scene, with an industrial autonomous printer of their own. HP’s SitePrint has a workflow with potentially a few additional steps and less accuracy. Compatible with 3 major total station providers, the HP printer does require this third party tool. As a leader in the printing space, various ink options give SitePrint the ability to modify for various surfaces. This has a projected release in 2023.

Civ Robotics remote controlled CivDOT can layout outdoors, in all terrain conditions. CivDOT can mark survey information with spray paint, dashed lines, or laser points. This technology has tilt correction with a 10” clearance and is compatible with top brands of GNSS receivers, collecting elevation and location.

In the future, do we see mixed reality making its way into this space? With spatial mapping, only two surfaces are needed for alignment, assuming there are walls or vertical surfaces. Today, using mixed reality would have notably less accuracy. GPS guidance could provide outdoor layout without a separate piece of hardware.

There is constant development on these solutions. As we gather more data and experience working with tools, we can identify potential improvements, like sustainable marking materials and a moving printer within the robots, to enable access anywhere, even up to edges.

Stay tuned for where we point the next!

Sources https://www.dustyrobotics.com/fieldprinter https://www.turnerconstruction.com/uploads/Turner-Innovation-Advancing-Robotics-in-Construction-Dusty-Robotics-Pilot.pdf Picking layout printer tools : https://20180565.fs1.hubspotusercontent-na1.net/hubfs/20180565/6%20Tips_Automated_5-12-2023.pdf https://www.gly.com/insights-news/gly-dusty-our-latest-robot-partnership (4) https://www.hp.com/us-en/printers/site-print/layout-robot.html?jumpid=ps_us_go_mk_se_cm017549_awa_x&gad=1&gclid=CjwKCAjwseSoBhBXEiwA9iZtxujsgXx_vdcuRLuKbMloeBJ3BooG1bFWjoprNgTv1brpksVFzI9QiRoCBDoQAvD_BwE